Understanding Valve Actuator Basics and Core Functions

What is a valve actuator and why it matters in system automation

Valve actuators work by turning energy sources into actual movement for valves, so operators don't have to keep adjusting them manually all day long. The Flow Control Institute reported back in 2024 that these little machines cut down on mistakes made by people working around pipelines, sometimes as much as 62%. When factories install these actuators throughout their systems, they get some pretty big advantages. Plants can run nonstop without needing constant attention from workers. Operators can monitor everything remotely through those fancy SCADA systems now. And there's also less risk involved when dealing with dangerous stuff like chemicals or high pressure steam that might otherwise cause accidents if someone forgets to adjust something properly at just the right moment.

Primary types of valve actuators: pneumatic, electric, and hydraulic

Three dominant actuator technologies serve distinct industrial needs:

- Pneumatic actuators use compressed air for rapid response, ideal for oil/gas shutoff valves requiring <1-second closure.

- Electric actuators offer pinpoint positioning accuracy (±0.1°), commonly deployed in HVAC and water treatment throttling.

- Hydraulic actuators generate up to 50,000 lbf thrust, making them essential for dam gates or large-scale slurry processing.

Rotary vs. linear motion in actuators: Matching the movement type to valve operation

Valve-actuator pairing hinges on motion alignment:

| Motion Type | Valve Applications | Key Requirements |

|---|---|---|

| Rotary | Ball, Butterfly valves | 90°-120° rotation capability |

| Linear | Gate, Globe valves | Continuous stem thrust |

Using rotary actuators on multi-turn globe valves causes incomplete sealing, risking leaks exceeding 15 psi in steam systems. Conversely, linear actuators on butterfly valves waste 30–40% of their stroke range.

Matching Valve Actuator to Common Valve Types: Ball, Butterfly, Gate, and Globe

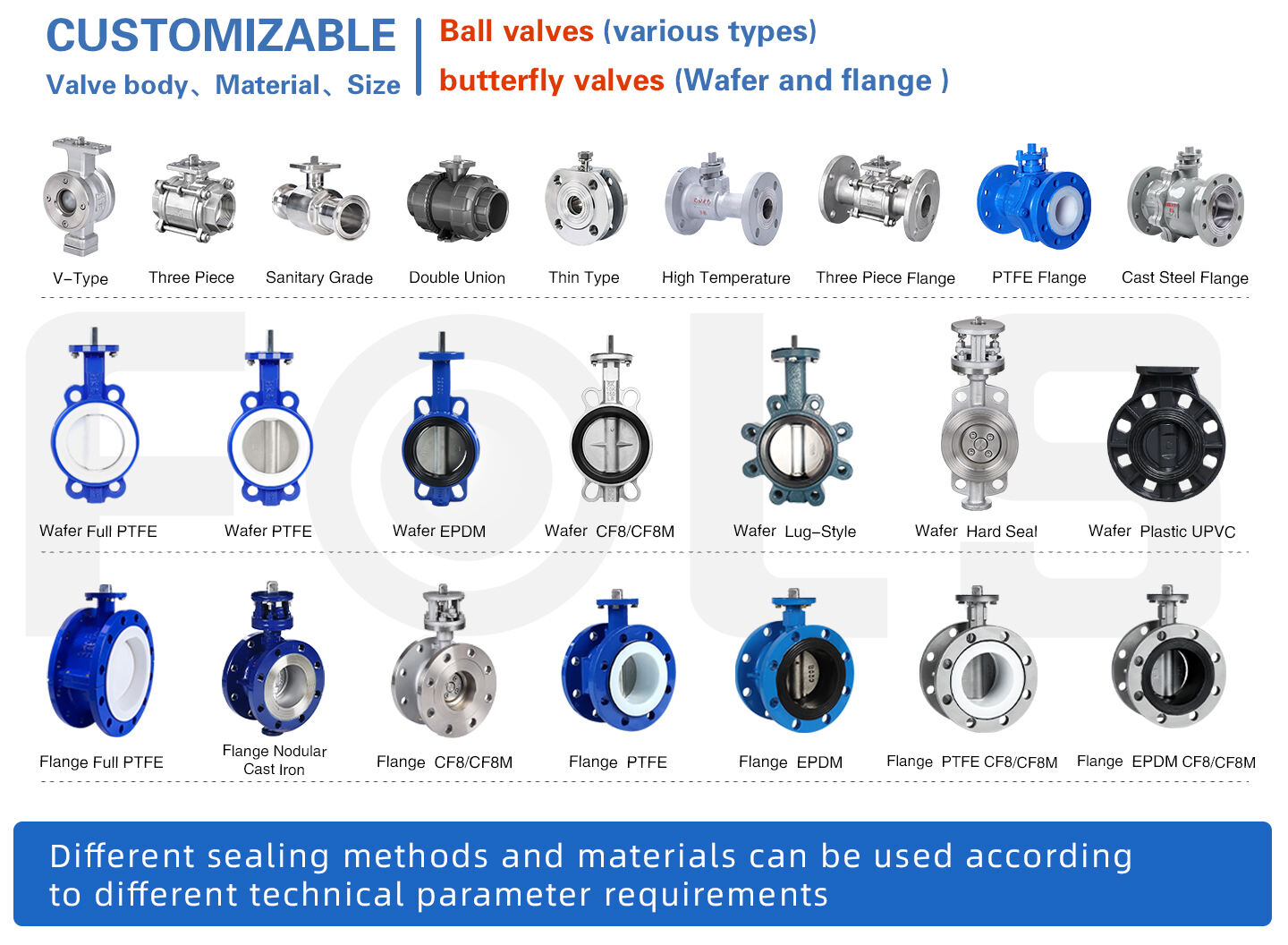

Ball and butterfly valves with rotary actuators: Why quarter-turn compatibility is critical

Both ball valves and butterfly valves need rotary actuators that can handle exactly 90 degrees of rotation for good sealing and proper control of fluid flow. These valves work on a quarter turn principle, so the actuator must generate enough starting torque to get past the initial friction but still move smoothly when the system is pressurized. When the torque specs don't match what's needed, problems happen. Valves might not close completely or wear out faster than they should. This becomes especially problematic in systems with high pressure because of something called valve chatter. Studies show this chatter can actually cut down on seal effectiveness by around 40 percent over time, which means leaks and maintenance headaches down the road.

Gate and globe valves with linear actuators: Ensuring multi-turn precision

Linear valve actuators work best when we need those slow, controlled movements for gate and globe valves. Most multi-turn systems require actuators that can maintain steady pushing power across about 5 to 20 complete rotations. The force needed usually falls somewhere between 1500 Newtons and 8000 Newtons depending on what kind of industrial valve we're talking about. Getting the alignment right between how far the actuator stem moves and the actual valve threads is really important too. When this doesn't match up properly, it causes binding problems especially in rising stem designs. This becomes a big issue in water treatment plants and steam systems where even tiny misalignments at the millimeter level can lead to serious leakage problems down the line.

Common mismatches and operational failures due to incorrect actuator-valve pairing

Putting rotary actuators on linear valves is responsible for about 62 percent of early seal failures according to maintenance records from the past year. There are several other common mistakes too. One big problem happens when people install electric actuators that aren't strong enough for high torque butterfly valves. This actually triples the chance of motors burning out. Another issue comes up frequently with wrong voltage supplies being used in areas where explosions could happen. When these things go wrong, what typically happens? Well, systems respond much slower than they should, sometimes taking over two whole seconds just to shut down in emergencies. Or worse still, valves don't complete their full movement range, which can really mess up production processes and safety protocols.

Sizing the Valve Actuator: Torque, Thrust, and Environmental Influences

Understanding Breakaway and Running Torque in Rotary Valve Applications

The force required to get a valve moving from a standstill position (known as breakaway torque) is typically 30 to 50 percent higher than what's needed once it's already in motion (running torque), especially in systems under high pressure. Take for instance a standard 10 inch ball valve dealing with 600 psi steam pressure. Such a setup might need around 1200 pound feet of torque just to start moving, but only about 800 pound feet while continuing operation. Why this happens? Well, it has everything to do with how hard the seat materials are and the sealing forces at play. Industry experience tells us that when actuators aren't sized properly for these requirements, they end up being responsible for roughly one out of every five valve failures across manufacturing facilities nationwide.

Calculating Thrust Requirements for Multi-Turn Gate and Globe Valves

Getting the right amount of force for linear actuators on gate valves is all about calculating how much thrust they need to push past both the stem friction and whatever pressure the media inside creates. Take for example a standard 6 inch ANSI class 900 globe valve working with thick crude oil at around 300 degrees Fahrenheit. These babies typically need about 12,000 pounds of force to operate properly. That's actually 40 percent more than what would be needed if the same valve was dealing with plain old water instead. The difference comes down to those seals getting tighter when handling viscous materials. And here's something interesting many folks overlook: going too big on the actuator size isn't always better. Just bumping up the capacity by 15% can actually cut the life expectancy of the whole system by anywhere from three to five years because the gears end up wearing out much faster under unnecessary stress.

Impact of Media Pressure, Temperature, and Viscosity on Actuator Sizing

Hydrocarbon processing plants report 22% higher actuator failures in cryogenic (-320°F) versus ambient conditions. High-viscosity media like molasses demand a 25% torque margin during cold startups, while slurries accelerate bearing wear by 60%. Pressure spikes above 1.5x rated capacity account for 31% of diaphragm failures in pneumatic models.

Industry-Standard Formulas and Software Tools for Accurate Actuator Sizing

| Calculation | Formula | Application |

|---|---|---|

| Rotary Torque | T = (π × P ÷ D³) / 1.5 | Ball/butterfly valves |

| Linear Thrust | F = π/4 × d² × P | Gate/globe valves |

| Leading automation providers now integrate CFD simulations with real-time pressure data, reducing sizing errors by 73% compared to manual methods. |

Ensuring Compatibility: Mounting, Materials, and Environmental Protection

Flange standards (ISO, DIN, ANSI) and mounting interface alignment

Proper alignment of mounting interfaces prevents mechanical stress and seal failures. Adherence to ISO 5211, DIN 3337, or ANSI B16.5 flange standards ensures 97% of actuators maintain torque transmission efficiency across 10,000+ cycles (Projectmaterials, 2017). Mismatched flanges increase leakage risks by 23% in high-pressure gas applications due to uneven load distribution.

Environmental challenges: Explosion-proofing, IP ratings, and corrosive conditions

For installations in hazardous areas, it's essential to have actuators that come with proper ATEX or IECEx certifications along with IP67 or IP69K ratings so they can handle both dust getting inside and those tough high pressure wash downs. When dealing with salt water environments specifically, stainless steel type 316L actuators tend to resist corrosion about 82 percent better compared to aluminum ones after around five years of service. The thing is, operators need to make sure their elastomer seals EPDM or Viton are suitable for whatever temperatures the media reaches, especially if it goes above 150 degrees Celsius otherwise these seals will start breaking down over time.

Material compatibility between valve bodies and actuator components

About one third of all actuator mounting problems in chemical facilities actually come down to galvanic corrosion when different metals touch each other. Most industry specs suggest getting the metal types right from the start. Take carbon steel valves for instance they work best with those ASTM A276-316 actuators especially where there's lots of chloride around. For really important setups engineers turn to the ASTM Piping Materials Match Table. This helps match how much materials expand when heated so nothing cracks apart during those inevitable temperature changes that happen throughout plant operations.

Future-Proofing Your Selection: Smart Actuators and Operational Efficiency

Integration of IoT-enabled Electric Actuators for Real-Time Monitoring

Valve actuators with IoT features now track performance in real time thanks to built-in sensors and wireless connections. The systems send information about torque levels, positioning, and operating cycles to central control panels, which helps spot problems before they become serious. Think about worn seals or motors working too hard these can all be caught earlier this way. Plants that switched to smart electric actuators saw a pretty big drop in unexpected shutdowns around 32% less according to field reports. Real time data just makes sense for maintenance planning and keeping operations running smoothly day after day.

Predictive Maintenance Using Embedded Sensors in Pneumatic Actuators

Advanced pneumatic models now incorporate vibration and pressure sensors that analyze air consumption patterns to detect leaks or diaphragm wear. Deviations in cycle times exceeding ±15% trigger maintenance alerts, allowing repairs during planned outages. Plants using these predictive systems achieve 26% longer service life compared to time-based maintenance.

Cost, Reliability, and Maintenance: Balancing Smart Technology With Application Needs

While IoT-enabled actuators carry a 40–60% higher upfront cost, their value is justified in critical applications such as chemical processing, where failure prevention outweighs initial investment. Prioritize smart features when addressing:

- Exposure to corrosive media requiring condition monitoring

- Safety-critical shutoff valves needing failover redundancy

- Energy-intensive processes where consumption analytics deliver savings

Hybrid solutions, such as retrofitting basic sensors to existing actuators, offer cost-effective pathways for smaller operations seeking incremental upgrades.

FAQ

What are the main types of valve actuators?

Valve actuators can be categorized into three primary types: pneumatic, electric, and hydraulic. Each serves specific industrial needs based on speed, precision, and force requirements.

How do I match an actuator to my valve?

The key to matching an actuator to a valve is understanding the motion type required—rotary or linear—and ensuring compatibility with valve torque and thrust requirements.

What are common mistakes in actuator-valve pairing?

Common errors include pairing rotary actuators with linear valves, using electric actuators not strong enough for high torque applications, and mismatches in voltage supply in explosive environments.

Why is actuator sizing important?

Proper actuator sizing ensures reliability and minimizes the risk of premature wear. It requires accurate calculations of breakaway torque and thrust requirements tailored to valve specifications and operating conditions.

What's the advantage of using IoT features in actuators?

IoT-enabled actuators provide real-time monitoring capabilities, enhancing predictive maintenance and reducing unexpected shutdowns by detecting potential issues early.

Table of Contents

- Understanding Valve Actuator Basics and Core Functions

- Matching Valve Actuator to Common Valve Types: Ball, Butterfly, Gate, and Globe

- Sizing the Valve Actuator: Torque, Thrust, and Environmental Influences

- Ensuring Compatibility: Mounting, Materials, and Environmental Protection

- Future-Proofing Your Selection: Smart Actuators and Operational Efficiency

- FAQ