Key Components of an Electric Valve System: Actuator, Stem, Seat, and Body

Every electric valve system relies on four critical components working in concert:

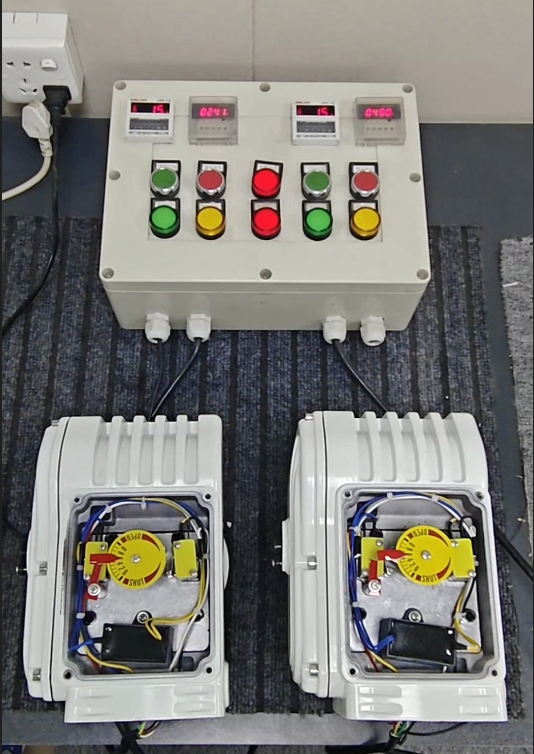

- Actuators convert electrical energy into mechanical motion

- Stems transfer actuator force to valve closures

- Seats form leak-tight seals when valves close

- Bodies withstand system pressures and flow conditions

Industry studies show actuator-related failures account for 34% of electric valve malfunctions (Flow Control Journal 2023), emphasizing the need for robust component design.

Role of Electronic and Smart Valve Technology in Modern Control Systems

Advanced systems now integrate IoT sensors and self-diagnostic algorithms to monitor real-time performance metrics, auto-adjust for pressure and temperature fluctuations, and predict maintenance needs through trend analysis. This evolution reduces human intervention by 62% in process industries while improving response times (Automation Today 2023).

Interconnection Between Control Signals and Actuator Functionality

Precision control depends on uninterrupted communication between 4-20 mA control signals and actuators' torque outputs. Signal degradation can cause positional drift, delayed response cycles, and increased hysteresis effects. Regular calibration ensures minimal signal loss across connectors and terminal blocks.

Common Electric Valve Problems: Stiction, Deadband, Hysteresis, and Their Causes

| Issue | Primary Causes | Impact on Operations |

|---|---|---|

| Stiction | Contaminated stems (67% cases) | Delayed valve response |

| Deadband | Worn gear teeth (41% occurrence) | Flow rate inaccuracies |

| Hysteresis | Temperature warping | Position repeatability loss |

Recent industry analyses show 82% of these issues become detectable through quarterly torque signature tests.

Implementing Preventive and Predictive Maintenance Strategies

Differences Between Preventive and Predictive Maintenance for Electric Valves

Preventive maintenance relies on scheduled inspections and component replacements based on time or usage thresholds, while predictive maintenance leverages real-time sensor data and AI analytics to anticipate failures. A 2023 industry study found predictive strategies reduce unplanned downtime by 35% compared to calendar-based approaches.

Routine Health Check-Ups and Performance Evaluation Schedules

Monthly inspections should include lubrication of stem assemblies, torque verification of actuator mounts, and electrical continuity tests. Facilities using quarterly performance evaluations report 22% fewer leaks than those with annual checks.

Using CMMS for Maintenance Scheduling and Tracking

Computerized Maintenance Management Systems (CMMS) automate work orders and track valve lifecycle data, enabling teams to prioritize high-risk assets. Plants implementing CMMS reduce labor costs by 18% through optimized task sequencing.

Monitoring Wear and Tear in Moving Parts Over Time

Infrared thermography and vibration analysis help detect early signs of gear train wear in actuators. Industry data shows facilities monitoring six or more performance parameters achieve high first-pass repair success rates for sticking valves.

Reactive vs. Proactive Maintenance: Cost Implications and Industry Insights

Proactive strategies yield a 5:1 ROI over reactive approaches by preventing catastrophic failures. According to a recent maintenance efficiency report, manufacturers using combined preventive/predictive programs spend significantly less on emergency valve repairs than competitors relying on breakdown maintenance.

Detecting and Preventing Leaks Through Regular Inspection

Best Practices for Regular Inspection and Early Leak Detection

Finding leaks before they become problems means doing regular checks visually, using ultrasonic equipment, and sometimes thermal imaging to spot those tiny cracks or weak spots in seals.

Pressure Testing and Visual Audits to Prevent System Failure

Testing under pressure helps check if seals hold up when things get tough, while looking around visually can spot problems like rust spots, broken casings, or parts that just don't line up right.

Case Study: Identifying Micro-Leaks Before Catastrophic Failure

A local chemical facility saved significant costs on potential downtime when workers spotted tiny cracks in a ball valve's stem seal during regular ultrasonic checks. This highlights why investing in detection systems makes sense financially.

Troubleshooting Actuator Malfunctions and Performing Valve Repairs

Signs of Actuator Malfunction in Electric Valve Systems

Erratic valve movement, delayed response to control signals, or total unresponsiveness often indicate actuator issues. Research shows that the majority of actuator failures stem from degraded diaphragm materials or corroded wiring connections.

Step-by-Step Diagnostic Process for Stuck or Unresponsive Actuators

- Power Verification: Confirm the actuator receives stable voltage using a multimeter

- Signal Testing: Check control circuit integrity by measuring signals at the actuator terminals

- Mechanical Inspection: Manually operate the valve to identify physical obstructions

Testing Electrical Signals and Feedback Loops During Troubleshooting

Modern electric valves rely on precise feedback loops between control systems and actuators. Use loop calibrators to verify signal accuracy and monitor positioner responses.

Common Valve Issues: Leakage, Sticking, and Seal Degradation

| Failure Type | Root Causes | Immediate Actions |

|---|---|---|

| Internal Leakage | Worn seat rings Corroded discs |

Lap sealing surfaces Replace damaged components |

| Valve Sticking | Contaminated lubricants Thermal expansion |

Ultrasonic cleaning Adjust bonnet bolting torque |

Safe Disassembly, Repair Procedures, and Post-Repair Verification

Always de-energize and depressurize systems before disassembling electric valves. Critical steps include documenting original stem packing compression levels and performing post-repair tests to confirm proper functionality.

Ensuring Safety, Efficiency, and Future-Readiness in Valve Maintenance

Safety Protocols During Electric Valve Maintenance to Protect Personnel and Equipment

Implementing lockout/tagout (LOTO) procedures and wearing arc-flash PPE prevents workplace injuries during electric valve servicing. Regular hazard assessments of control circuits and pneumatic supply lines reduce risks of unexpected actuation.

Maximizing Operational Efficiency Through Calibrated, Reliable Valve Performance

Quarterly calibration of valve positioners and actuators maintains response accuracy, minimizing process deviations. Tracking key performance indicators like cycle time reduces energy waste in industrial flow systems.

Recommended Tools and Best Practices for Long-Term Electric Valve Reliability

Essential maintenance tools include non-invasive infrared thermometers, smart torque testers, and dielectric grease for moisture-sensitive electrical contacts. Regular lubrication of gland seals extends service intervals.

Future Trends: IoT-Enabled Smart Valves and AI-Driven Predictive Maintenance

IoT sensors embedded in equipment can track valve performance in real-time, providing insights into potential issues before they occur. Smart systems utilizing sensor data are becoming increasingly efficient at predictive maintenance.

FAQ Section

What are the primary components of an electric valve system?

An electric valve system consists of actuators, stems, seats, and bodies, each playing a crucial role in converting energy and maintaining system integrity.

How does predictive maintenance differ from preventive maintenance?

Predictive maintenance uses real-time data and analytics to foresee failures, whereas preventive maintenance is based on scheduled inspections and routine component replacement.

What are common issues in electric valve systems?

Common issues include stiction, deadband, and hysteresis, often caused by factors such as contaminated stems and worn gear teeth.

How can IoT technology aid electric valve maintenance?

IoT technology allows for real-time monitoring and data analysis, which improves predictive maintenance and reduces unexpected failures.

Table of Contents

- Key Components of an Electric Valve System: Actuator, Stem, Seat, and Body

- Role of Electronic and Smart Valve Technology in Modern Control Systems

- Interconnection Between Control Signals and Actuator Functionality

- Common Electric Valve Problems: Stiction, Deadband, Hysteresis, and Their Causes

-

Implementing Preventive and Predictive Maintenance Strategies

- Differences Between Preventive and Predictive Maintenance for Electric Valves

- Routine Health Check-Ups and Performance Evaluation Schedules

- Using CMMS for Maintenance Scheduling and Tracking

- Monitoring Wear and Tear in Moving Parts Over Time

- Reactive vs. Proactive Maintenance: Cost Implications and Industry Insights

- Detecting and Preventing Leaks Through Regular Inspection

- Troubleshooting Actuator Malfunctions and Performing Valve Repairs

- Signs of Actuator Malfunction in Electric Valve Systems

- Step-by-Step Diagnostic Process for Stuck or Unresponsive Actuators

- Testing Electrical Signals and Feedback Loops During Troubleshooting

- Common Valve Issues: Leakage, Sticking, and Seal Degradation

- Safe Disassembly, Repair Procedures, and Post-Repair Verification

-

Ensuring Safety, Efficiency, and Future-Readiness in Valve Maintenance

- Safety Protocols During Electric Valve Maintenance to Protect Personnel and Equipment

- Maximizing Operational Efficiency Through Calibrated, Reliable Valve Performance

- Recommended Tools and Best Practices for Long-Term Electric Valve Reliability

- Future Trends: IoT-Enabled Smart Valves and AI-Driven Predictive Maintenance

- FAQ Section