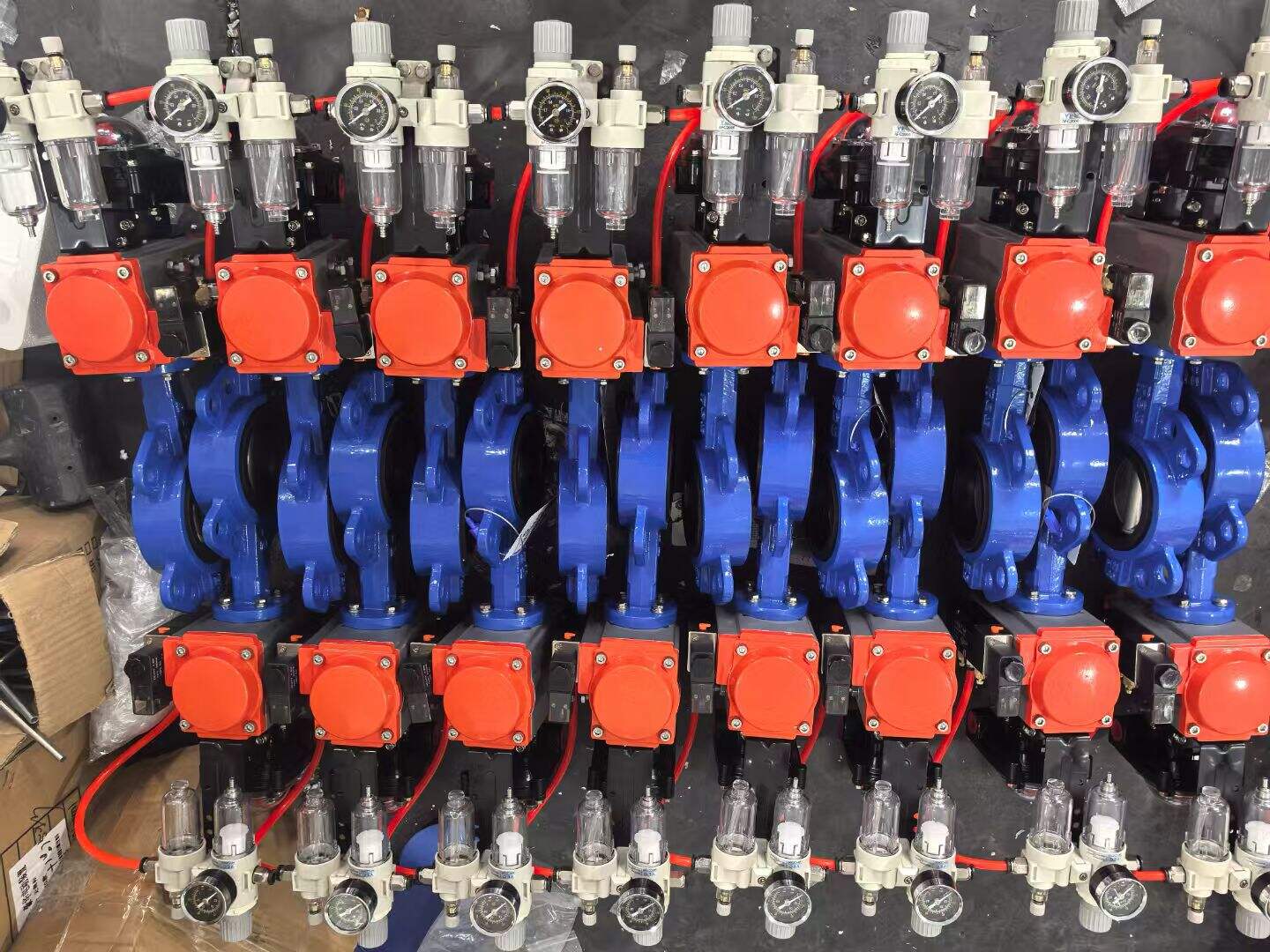

How Butterfly Valves Ensure Reliable Shutoff in Fire Protection Systems

Quarter-Turn Mechanism for Rapid Activation During Emergencies

Butterfly valves work by rotating just 90 degrees to shut off completely within less than a second. That makes these valves really good for fire protection systems where getting the water stopped fast matters most. When there's a fire emergency, being able to control the flow through sprinklers and standpipes right away can save buildings from major damage. Most people aren't aware that traditional gate valves need between six to ten full turns to close properly. Imagine trying to do that while fighting a fire! The butterfly valve's simple quarter turn design cuts down on mistakes when someone needs to act quickly but their hands are shaking from stress.

Sealing Performance Under High-Pressure and High-Flow Conditions

Modern butterfly valves are built to handle pressures all the way up to 250 PSI and still keep those leaks at bay even when things get really intense. The seats inside these valves use some pretty advanced materials like reinforced EPDM rubber and PTFE which help them deal with temperature changes without breaking down. And the discs themselves are machined with such precision that they don't warp or bend when there's a sudden spike in pressure. Labs that have been approved by UL and FM did some independent tests too. They ran these valves through 10,000 cycles following NFPA 25 standards and found absolutely no leakage. That kind of performance over time speaks volumes about their reliability in real world applications.

Design Features Ensuring Durability and Leak-Free Operation

Three core features ensure sustained performance:

- Stainless steel discs with corrosion resistance rated for over 50 years in wet environments

- Dual-seal stem packing that eliminates shaft interface leaks

- Fire-safe construction validated to endure 1,500°F for 30 minutes (per API 607/BS 6755)

These attributes allow butterfly valves to operate continuously without maintenance—essential for fire system components that remain idle for extended periods.

Comparison of Resilient Seated vs. High-Performance Butterfly Valves in Fire Systems

| Feature | Resilient Seated Valves | High-Performance Valves |

|---|---|---|

| Pressure Rating | 150 PSI (Class 150) | 300 PSI (Class 300) |

| Temperature Range | -20°F to 200°F | -50°F to 450°F |

| Seal Material | EPDM/NBR Elastomers | Graphite/Metal Seated |

| Typical Use | Standard commercial buildings | High-rise/Industrial facilities |

Resilient seated valves are suitable for most commercial applications, while high-performance models are necessary in chemical plants or structures exceeding 75 feet, where enhanced fire resistance and durability are required.

Compliance with NFPA and Industry Standards for Fire Protection Applications

Meeting NFPA 14 and NFPA 25 Requirements for Sprinkler and Standpipe Systems

Butterfly valves help meet requirements set by NFPA 14 for standpipe and hose systems, plus NFPA 25 covering inspection and maintenance of water-based fire protection systems. These standards require dependable ways to shut off flow and routine pressure checks. The valves have strong sealing areas that don't wear out easily, plus they resist rust even in harsh conditions, so water flows reliably when emergencies happen. According to a recent industry study from 2025, nearly 9 out of 10 problems with fire systems actually start with faulty valves. That's why choosing valves that follow NFPA guidelines isn't just about paperwork it literally keeps buildings safe during critical moments.

Fire-Safe Testing per ANSI/API 607 and Material Certifications for Hazardous Environments

In dangerous work areas, butterfly valves need to go through the ANSI/API 607 fire test standards. These tests basically put the valve under direct flames for half an hour and check if the seals still hold up. The parts themselves matter too. Ductile iron bodies paired with EPDM seats can handle heat up to around 400 degrees Fahrenheit or 204 Celsius, plus they work at pressures over 175 pounds per square inch. That makes these valves suitable for places where chemicals are handled or manufactured. Getting UL or FM certification is also important because it shows these valves play nice with fire resistant pipes made from materials like carbon steel and CPVC. This compatibility factor really boosts overall safety when working in environments where explosions or fires could happen unexpectedly.

Wafer vs. Grooved Butterfly Valves: Selection for Fire Protection Piping

Installation Considerations and Space Efficiency in System Design

The wafer butterfly valve has this really compact design that makes it perfect for cramped installations where there's barely enough room between flanges – usually just 2 to 3 inches. When installing these valves between regular pipe flanges, plumbers need to remember the proper cross pattern when tightening bolts so the seating doesn't get warped. On the other hand, those grooved end valves come with factory made couplings that simply attach to the rolled grooves on pipes. This setup cuts down on installation time significantly, around 35 percent according to NFPA 25 standards from last year. Sure, wafer models cost about 15 to 20 percent less upfront, but the grooved ones win out when speed matters most. That's why many contractors prefer them for retrofits where getting everything aligned properly can be such a headache.

Maintenance Accessibility and Repair Advantages in Critical Applications

The grooved butterfly valve design makes maintenance much easier when repairs are needed. Technicians don't have to take apart the entire valve body just to disconnect couplings, so they can replace piping downstream without compromising the whole system. This really matters in situations where there's still an active fire risk somewhere in the building. Wafer style valves tell another story though. Getting at them means taking all those flange bolts apart, which adds roughly half an hour to fifty minutes of extra downtime according to what we've seen on site. When it comes to tall buildings that need systems resistant to vibrations, grooved connections handle both earthquake movements and sudden water hammer impacts better than other options. Plus, these connections keep working without leaks even under such stressful conditions.

Compatibility With Existing Piping Systems and Vibration Resistance

The grooved butterfly valves show pretty good compatibility around 90 something percent with modern CPVC and steel sprinkler lines according to Fire Protection Materials Reports from last year, mainly because their couplings fit standard sizes. The way these valves are designed actually reduces vibrations quite a bit about forty percent less than those rigid flange connections which makes them especially useful on pump discharge lines where vibration can be a real problem. Wafer style valves tend to perform okay when retrofitting older flanged systems, but maintenance crews usually need to check and tighten bolts once a year. We're talking roughly two or three service calls per valve in city environments over time. Both valve styles satisfy the NFPA 14 requirement of at least 250 pounds per square inch for standpipes, but installers generally go for the grooved ones in earthquake prone regions since they handle ground movement better.

Butterfly Valves vs. Gate Valves: Performance and Cost Benefits in Fire Safety

Lightweight design, smaller footprint, and lower lifecycle costs

According to recent data from the flow control sector in 2023, installing butterfly valves instead of traditional gate valves can cut costs anywhere between 30 to 50 percent. The compact wafer design takes up roughly two thirds less room than standard alternatives, which makes them ideal for tight spaces where equipment is already crammed together. We're talking about significant weight reductions too - sometimes as much as 75% thanks to modern polymer seats and better engineering practices. Maintenance bills drop substantially over time as well. A study by FM Global back in 2019 found that these valves require far less upkeep, saving around 45% on maintenance expenses over ten years because they don't need constant adjustments or lubrication like older gate valve systems do.

Superior operational reliability in infrequently used fire protection systems

Quarter turn mechanisms stop stem seizure, which happens all too often with gate valves sitting idle for years on end. According to testing done by independent researchers, butterfly valves stay ready to go at around 98.6 percent after five years without being used, way ahead of gate valves that only hit about 82 percent reliability (as reported in NFPA Journal 2022). The rubbery seats made from resilient elastomers keep those seals intact even when temperatures fluctuate and vibrations occur. This actually solves one of the main problems gate valves face in fire protection systems that sit unused until they're needed most.

Case study: Retrofitting gate valves with butterfly valves in a high-rise municipal building

The city hall tower, standing at 40 stories tall, swapped out all those old gate valves for lug-style butterfly models across its system. Maintenance crews now spend 72% fewer hours each year fixing these components compared to before the upgrade. During emergency simulations last quarter, firefighters noticed they could reach problem areas 28 seconds faster per valve location. Water companies reported a 40% drop in losses from leaks after installation, according to industry data from IAFF back in 2021. Looking at the building's structure, engineers found that replacing those heavy valves actually reduced weight in the mechanical rooms by around 2.1 tons. That extra space turned out to be really valuable for adding more fire pumps without needing any major renovations to the facility.

FAQ

What is the main advantage of using butterfly valves in fire protection systems?

Butterfly valves offer a quick quarter-turn mechanism that allows for rapid shutoff of water flow, which is crucial during fire emergencies. This fast activation can save buildings from major damage compared to traditional gate valves that require multiple full turns to close.

How do butterfly valves perform under high-pressure conditions?

Modern butterfly valves are designed to handle pressures up to 250 PSI while maintaining a leak-free operation. They use advanced materials such as reinforced EPDM rubber and PTFE for enhanced durability, even under sudden pressure spikes.

Are butterfly valves durable over long periods of inactivity?

Yes, butterfly valves are constructed with materials that resist corrosion and wear, ensuring they remain operational without maintenance for extended periods. They have a superior operational reliability rate of approximately 98.6% after five years without use.

What are the differences between wafer and grooved butterfly valves?

Wafer butterfly valves are compact and suitable for tight spaces, requiring careful installation to avoid warping. Grooved butterfly valves feature factory-made couplings for quick installation and easier maintenance, making them ideal for retrofitted systems and in seismic-prone areas.

Why are butterfly valves preferred over gate valves in fire safety?

Butterfly valves provide cost savings, a smaller footprint, and enhanced reliability. They require less maintenance, reduce installation time, and their lightweight design minimizes space and weight impacts, making them advantageous over traditional gate valves.

Table of Contents

- How Butterfly Valves Ensure Reliable Shutoff in Fire Protection Systems

- Compliance with NFPA and Industry Standards for Fire Protection Applications

- Wafer vs. Grooved Butterfly Valves: Selection for Fire Protection Piping

- Butterfly Valves vs. Gate Valves: Performance and Cost Benefits in Fire Safety

-

FAQ

- What is the main advantage of using butterfly valves in fire protection systems?

- How do butterfly valves perform under high-pressure conditions?

- Are butterfly valves durable over long periods of inactivity?

- What are the differences between wafer and grooved butterfly valves?

- Why are butterfly valves preferred over gate valves in fire safety?