Grunnleggende om pneumatisk smørflyte

Nøkkelkomponenter og designegenskaper

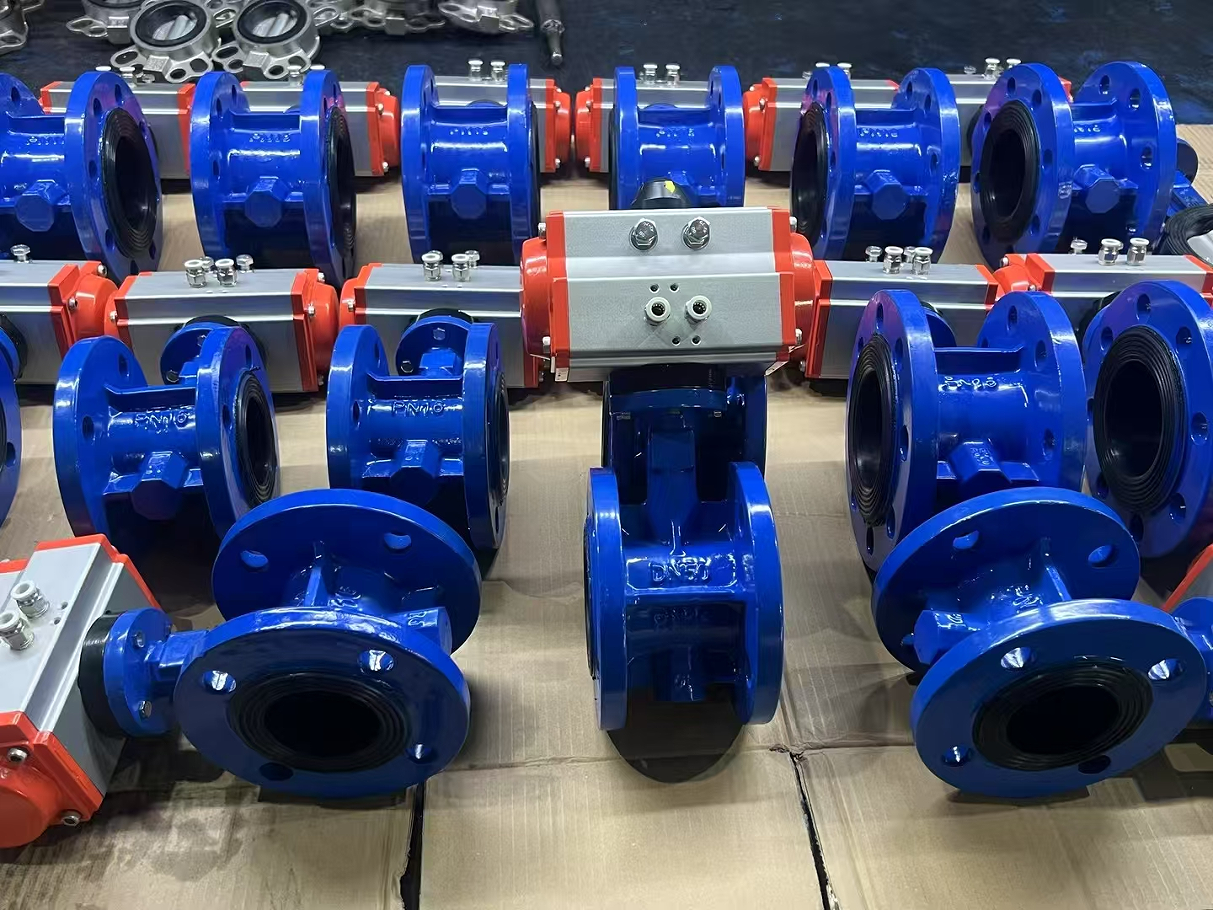

Pneumatiske butterfly-ventiler gir operatører fin kontroll over væskestrøm takket være sin unike konstruksjon og komponentarrangement. I sentrum av disse ventilene ligger den roterende skiven (vanligvis kalt butterflyen), som åpner og lukker inne i ventilkroppen for å regulere strømningshastigheter. Ventilkropper finnes i ulike materialer avhengig av bruksområdene – rustfritt stål for høy korrosjonsmotstand, PVC for kjemisk kompatibilitet, osv. Kroppen må tåle harde forhold og vare gjennom utallige sykluser. Viktige komponenter inkluderer ventilsætet som sikrer en god tetning mot lekkasje når ventilen er lukket, samt den pneumatiske aktuatoren som beveger skiven raskt og nøyaktig. Mange modeller har wafer-typen kropper som passer sikkert mellom eksisterende rørfanger, noe som gjør dem lettere å installere sammenlignet med andre ventiltyper. Når man kjøper disse ventilene, blir det avgjørende å sjekke ANSI-klassifiseringer, fordi de forteller ingeniører hvilke trykk- og temperaturnivåer ventilen kan håndtere sikkert i ulike driftsmiljøer.

Roller i flytende kontrollsystemer

Pneumatiske butterfly-ventiler er kritiske komponenter i væskestyringssystemer og hjelper med å regulere strømningshastigheter samtidig som systemtrykket holdes stabilt. Når operatører justerer ventilens posisjon, finjusterer de i praksis både trykknivåer og strømningsvolum for å tilpasse seg de behovene som ulike prosesser har i sektorer som petrokjemiske anlegg eller avløpsrensingsanlegg. Disse ventilene er konstruert for å redusere turbulens inne i rørledningene, noe som reduserer energitap og gjør at hele systemet kjører jevnere. Mange pneumatiske modeller fungerer nå sømløst med digitale kontrollpaneler og sender sanntidsdata tilbake til sentrale overvåkingsstasjoner for bedre prosesshåndtering. Sikkerhet er også en stor bekymring, siden disse ventilene stopper farlig tilbakestrømning som kan skade utstyr eller skape farlige forhold. Deres kompatibilitet med moderne automasjonsteknologier betyr at pneumatiske butterfly-ventiler ikke lenger bare er funksjonelle deler, men integrerte komponenter i sofistikerte væskehåndteringssystemer som brukes i moderne produksjonsoperasjoner.

Ved å forstå disse grunnleggende aspektene, kan man effektivt bruke pneumatisk smørflyte i ulike anvendelser, og utnytte deres versatilitet og pålitelighet.

Arbeidsmekanisme for pneumatisk aktivering

Pneumatisk aktuatoroperasjoner

Pneumatiske aktuatorer utgjør en nøkkelkomponent i fluidkontrollsystemer, der de omdanner komprimert luftkraft til mekanisk bevegelse som åpner og lukker svingdørventiler i industrielle anlegg. Denne omformingen skjer gjennom enten lineære eller rotære bevegelsesmønster, men rotasjonsversjoner fungerer vanligvis bedre for svingdørventiler fordi de rett og slett utfører jobben raskere. Aktuatorer finnes i ulike konfigurasjoner avhengig av behovet i feltet. Noen er dobbeltrikende, mens andre har fjærereturnmekanismer, og hver av dem påvirker hvordan de faktisk fungerer i daglig drift. Når det gjelder rask responstid, presterer disse aktuatorer virkelig godt i situasjoner hvor hurtige justeringer er avgjørende, for eksempel under nødavstengninger eller når man finjusterer prosessparametere underveis. Men husk at forhold som ujevne lufttrykksnivåer eller ekstreme temperaturer kan påvirke driften negativt, så anleggsingeniører må sjekke dem regelmessig for å sikre at alt fungerer jevnt og unngå uventet nedetid.

Integrering med fluefuglsvemersystemer

Når pneumatisk aktuatorer kobles til sommerfuglventilsystemer, blir automatisering av strømningskontroll mye jevnere og mer nøyaktig enn med tradisjonelle metoder. Slike oppsett fungerer spesielt godt når de kobles til ting som PLC-er eller programmerbare logikkstyringer, som i praksis forteller aktuatorene nøyaktig hva de skal gjøre med millimeterpresisjon. Dette reduserer feil som oppstår når folk hele tiden må justere ventiler manuelt. I produksjonsanlegg og prosesseringsanlegg bestemmer hvor godt aktuatorer passer til sommerfuglventiler om et system vil kunne håndtere ulike oppgaver eller holde seg til én enkelt jobb. Det er også veldig viktig å få alt riktig justert under installasjonen, fordi til og med små feil her kan føre til store problemer senere. De fleste ingeniører kjører først datamodeller før noe installeres i felt. Disse simuleringene hjelper med å oppdage potensielle problemer tidlig, slik at utstyret fungerer pålitelig når det først er på plass, uten at tid og ressurser må gå til retting etter at det er satt i drift.

Trygghetsfunksjoner og nødstansavslutting

Pneumatiske butterfly-ventiler er utstyrt med innebygde feilsikre mekanismer som vil lukke ventilen automatisk ved strømavbrudd, noe som bidrar til å holde systemene intakte også i vanskelige situasjoner. Funksjonen for nødavstengning er svært viktig for å forhindre alvorlige ulykker, spesielt i farlige områder der det å følge sikkerhetsregler ikke er valgfritt, men obligatorisk. Å teste disse feilsikre funksjonene regelmessig er avgjørende for å være forberedt når noe går galt, og denne praksisen er i tråd med hva de fleste industrier krever når det gjelder sikkerhet. Mange ventildesign inkluderer faktisk reservesystemer som standard, noe som skaper ekstra beskyttelse mot feilfunksjoner. Denne typen redundans sikrer ikke bare at driften kan fortsette jevnt, men beskytter også mot kostbare utstyrsskader og beskytter arbeidere som ellers kunne stått ovenfor alvorlige risikoer dersom ventilene skulle svikte uventet under normal drift.

Fordeler i Industrielle Applikasjoner

Energieffektivitet og kostnadsbesparingar

Pneumatiske butterfly-ventiler skiller seg ut fordi de sparer energi, hovedsakelig fordi de skaper mindre trykktap gjennom systemet. Dette betyr at selskaper bruker mindre penger på pumping av væsker gjennom rørledninger. Muligheten til å finjustere strømningshastigheter betyr også mye, og reduserer driftskostnadene samtidig som det støtter grønnere produksjonsmetoder. Industrianlegg som bytter til bedre ventiltjeneste opplever ofte en reduksjon på rundt 30 % i energikostnadene, ifølge bransjerapporter. Vedlikehold er veldig viktig for å sørge for at disse ventilene fungerer korrekt over tid. En enkel sjekk hvert par måneder forhindrer sammenbrudd og forlenger levetiden med flere år, noe som sparer penger sammenlignet med å erstatte gamle ventiler. Å arbeide tett med utstyrssleverandører under den opprinnelige installasjonen hjelper til å finne de mest effektive modellene som er tilgjengelige. Mange bedrifter rapporterer betydelige kostnadsbesparelser allerede etter noen få år etter å ha gjort en slik investering.

Pålitelighet i høytrykksmiljøer

Pneumatiske sommerfuglventiler fungerer godt i høyt trykk, noe som gjør dem til et populært valg innen olje- og gassdrift samt kjemiske prosessanlegg. De fleste produsenter lager disse ventiler av sterke metalllegeringer som tåler hardt slitasje under normal drift. Før installasjon tester selskaper omfattende for å sikre at de tåler ekstreme forhold på arbeidsplassen. Feltteknikere melder jevnlig tilbake at ventiler som ikke knuser seg under varierende trykknivåer, sparer tid og penger i vedlikeholdskostnader. Å få riktig sertifisering fra organer som ISO er ikke bare papirarbeid – det viser faktisk at disse ventiler tåler de strenge kravene som sikkerhetsregler og ytelsesforventninger stiller i industrielle miljøer.

Kompatibilitet med automatiserte kontrollsystemer

Pneumatiske butterflyventiler fungerer veldig bra med automatiserte systemer som SCADA og DCS, noe som gjør det enklere å overvåke og kontrollere prosesser på tvers av ulike anlegg. Når fabrikker automatiserer sine operasjoner, sparer de tid på manuelle oppgaver og får jobbene gjort raskere i all hovedsak. Kommunikasjonen mellom disse systemene er også ganske fleksibel, slik at de raskt kan respondere når noe endrer seg i væskekontrolloppsettet. For eksempel oppnår anlegg som skifter til automatiserte ventiler ofte bedre produksjonsrater, fordi det blir færre feil og mindre utstyr står å gjøre ingenting. Selskaper som investerer i god automasjonsteknologi, får også verdifulle innsikter fra innsamlede data, som hjelper ledere med å ta smartere beslutninger om vedlikehold og driftsjusteringer.

Vanlige applikasjoner på tvers av industrier

Olje- og gassrørledningsforvaltning

Pneumatiske butterfly-ventiler spiller en nøkkelrolle i olje- og gassrørledningsdrift, hvor de kontrollerer strømningshastigheter og håndterer trykk effektivt. Disse ventilene reagerer raskt ved plutselige endringer i etterspørsel, noe som sikrer at drifta er trygg samtidig som den totale effektiviteten i rørledningsnettet økes. De fleste produsenter følger API-standarder fordi disse retningslinjene sikrer at utstyret fungerer pålitelig, også under krevende forhold som ekstreme temperaturer eller korrosive miljøer. Vedlikeholdspersonell inspiserer vanligvis disse ventilene hver få måneder for å oppdage tegn på slitasje før de utvikler seg til alvorlige problemer. En liten lekkasje i dag kan utvikles til en stor katastrofe senere dersom den ikke blir oppdaget. Utenfor de rene sikkerhetsaspektene fører riktig ventilfunksjon også til kostnadsbesparelser. Når alt fungerer som det skal, bruker pumpestasjonene mindre energi gjennom hele systemet, noe som gjør ressursdriften mer kostnadseffektiv på lang sikt for operatørene.

Kjemiske prosesseringssystemer

Pneumatiske butterfly-ventiler spiller en avgjørende rolle i kjemisk industri der nøyaktig regulering er viktigst, spesielt når man håndterer farlige stoffer. De fleste produsenter lager disse ventilene av materialer som motstår korrosjon, siden de må tåle harde kjemiske prosessbetingelser. Vanlig vedlikehold er ikke bare anbefalt – det er absolutt nødvendig i henhold til sikkerhetsstandarder, slik at disse viktige delene fortsetter å fungere feilfritt. Overgang til automatiserte versjoner av disse pneumatisk styrede ventilene gir bedre kontroll over prosessene, noe som betyr høyere kvalitet på ferdige produkter. Og la oss være ærlige, ingen ønsker ulykker. Derfor er kontinuerlig overvåking avgjørende, ikke bare for å oppfylle regulatoriske krav, men også for å sikre arbeidstakeres sikkerhet dag etter dag.

Vatnskjøter

Pneumatiske butterfly-ventiler er i stor grad arbeidshestene i vannbehandlingsanlegg, der de kontrollerer strømningshastigheter under filtreringsprosesser og når kjemikalier tilføres vannet. Det er faktisk denne kontinuerlige kontrollen av strømning som gjør at vannet fra kranen er sikkert nok til å oppfylle alle de myndighetenes reguleringer vi har på plass. Det som gjør disse ventilene så verdifulle, er deres evne til å raskt tilpasse seg når forholdene endres i løpet av dagen. Driftspersonell kan endre innstillinger underveis hvis det oppstår plutselige etterspørselspiker eller uventede endringer i råvannets kvalitet. Rutinemessige vedlikeholdskontroller er også helt avgjørende. Et enkelt oversettet tetningsutskiftning eller slitte komponenter kan føre til alvorlige forstyrrelser nedstrøms. Godt nytt? Nye innovasjoner innen ventildesign hjelper behandlingsanlegg med å redusere avfall og energiforbruk, samtidig som strenge kvalitetskontroller opprettholdes. Disse forbedringene handler ikke bare om å spare penger – de støtter direkte bredere bærekraftsinitiativ innen hele vannsektoren.

Regulering av luftstrøm i HVAC

Pneumatiske butterfly-ventiler forekommer overalt i VVS-systemer disse dager fordi de er så gode til å regulere luftstrøm og holde bygninger på behagelige temperaturer uten å kaste bort strøm. Det som gjør dem spesielle, er hvor nøyaktig de kan justere luftstrømmen avhengig av hvor mange som faktisk er i rommet. For eksempel reduserer disse ventilene automatisk strømmen etter at kontorer tømmes etter arbeidstid, noe som sparer penger på strømregningen uten å gjøre noen ubehagelig under normale driftsforhold. Det er også veldig viktig å holde disse ventilene ordentlig vedlikeholdt, siden selv små luftlekkasjer kan alvorlig redusere systemets effektivitet og øke vedlikeholdskostnadene over tid. Når de er koblet til moderne smart byggingsplattformer, blir de enda mer verdifulle verktøy for å overvåke innendørs luftkvalitet og nøyaktig se hvor mye energi forskjellige områder forbruker gjennom dagen. Etter hvert som bygningskoder blir strengere på energiforbruk og eiendomseiere søker etter måter å kutte driftskostnader på, fortsetter produsentene å utvikle bedre ventildesign som møter disse kravene samtidig som de hjelper bygninger til å kjøre grønnere.

Vedlikeholds beste praksiser

Rutinemessige inspeksjonsprotokoller

Vanlige sjekker av pneumatisk sommerfuglventiler er virkelig viktig hvis vi ønsker at de skal vare lenge og fungere ordentlig over tid. Den faktiske inspeksjonsprosessen innebærer å lete etter lekkasjer rundt tetningene, sjekke hvor mye slitasje som har oppstått på ulike deler, og sørge for at ventilen åpner og lukker korrekt når den skal. De fleste industrier anbefaler å gjøre disse inspeksjonene basert på hvor hardt ventilene arbeider hver dag. Å føre oppføringslogger over hva som finnes under inspeksjonene hjelper med å følge med på hvor godt ventilene tåler belastningen, og fanger opp små problemer før de utvikler seg til store hodebry senere. At ansatte får opplæring i gode inspeksjonsmetoder gjør også en stor forskjell. Når folk vet nøyaktig hva de skal lete etter og hvordan de skal teste ting riktig, blir hele vedlikeholdssystemet mer pålitelig og faktisk fungerer som det er tenkt, i stedet for bare å gå gjennom bevegelsene.

Lubrikasjon og seglbytte

Å få påført riktig mengde smøremiddel på de bevegelige delene inne i ventilene i pneumatisk butterfly ventiler betyr mye for jevn drift og redusert slitasje over tid. Hold deg til smøretidspunktene som produsenten anbefaler, og legg merke til hvor mye lenger ventilene faktisk varer under reelle driftsforhold. Glem ikke tetningene heller, disse må også skiftes jevnlig, enten i henhold til produsentens anbefalinger eller når de begynner å vise slitasjesmerker. Dette hjelper med å holde alt godt tetnet og forhindrer irriterende lekkasjer. Typen smøremiddel er også viktig ulike materialer reagerer forskjellig, så sjekk alltid hva som fungerer best for hver enkelt applikasjon. Gode vedlikeholdsdokumenter bør følge opp når smøring har skjedd og hvordan tetningene ser ut ved inspeksjoner. Å investere i kvalitetstetninger og gode smøremidler gir stor avkastning færre driftsstopper betyr mindre nedetid og mindre penger brukt på å reparere problemer som kunne vært unngått.

Felsøking av solenoidpenger

Når man skal håndtere problemer med magnetventiler, kan det hjelpe å starte med å se på hva som kan være galt med enten strømforsyningen eller lufttilførselen. Mange ganger åpner eller lukker ikke disse ventilene helt som de skal, noe som ofte løser seg selv etter små justeringer eller en grundig rengjøring. Det gir også mening å sjekke de elektriske komponentene regelmessig, da dette sørger for bedre drift og reduserer overraskelser når de slutter å fungere. Når du skal erstatte gamle ventiler, bør du vurdere hvor lenge de har vært i bruk og tidligere ytelsesrekorder, i stedet for å gjette deg frem. Personell som håndterer vedlikehold, må også ha riktig opplæring i å løse slike problemer, slik at mindre tid går tapt på å få alt til å fungere igjen. Det er også viktig at ansatte føler seg trygge på grunnleggende feilsøking for å holde driften i gang uten konstante avbrudd.