Fundamentals of Pneumatic Butterfly Valves

Key Components and Design Features

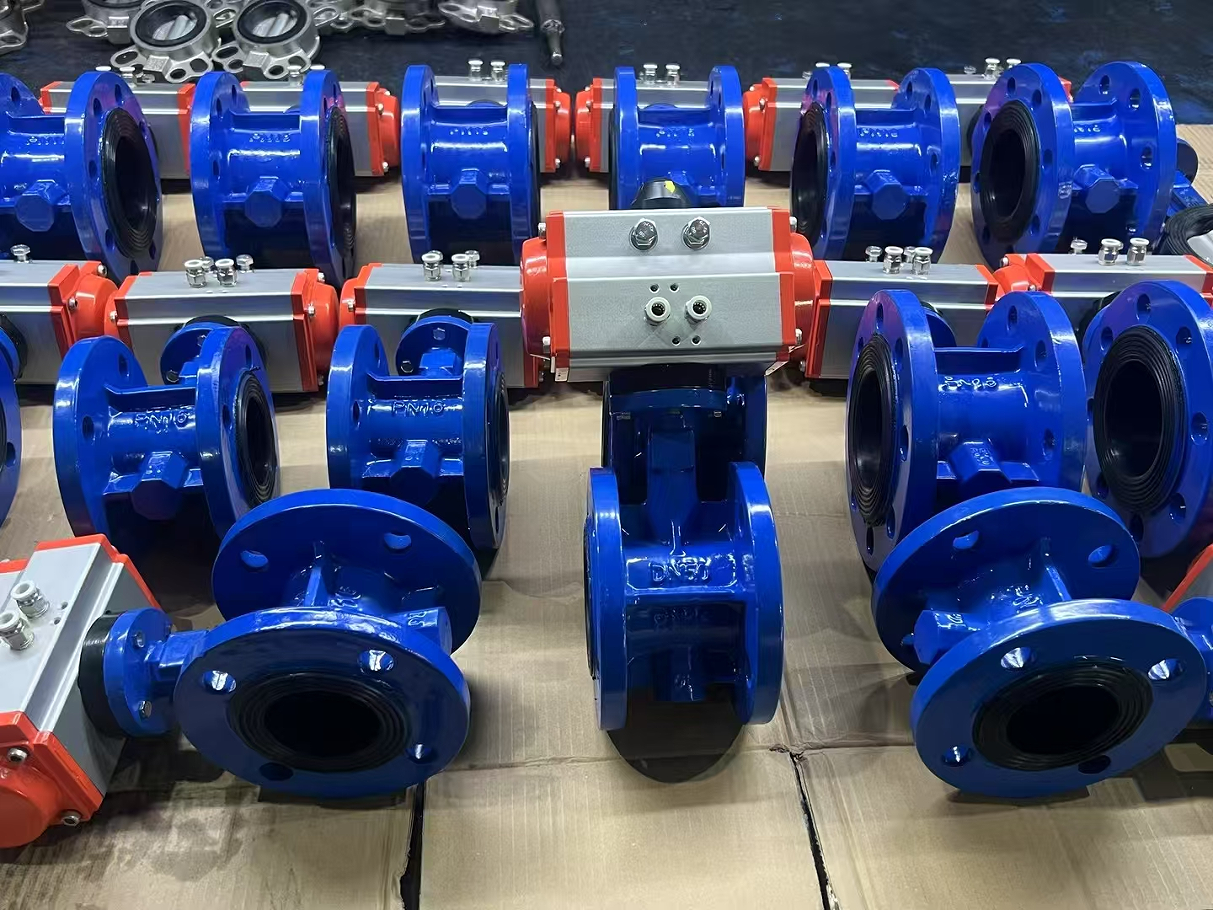

Pneumatic butterfly valves give operators fine control over fluid flow thanks to their unique construction and component arrangement. At the heart of these valves sits the rotating disc (commonly called the butterfly), which opens and closes inside the valve body to manage flow rates. Valve bodies come in different materials depending on application needs – stainless steel for high corrosion resistance, PVC for chemical compatibility, etc. The body itself needs to stand up to tough conditions while lasting through countless cycles. Important parts include the valve seat that creates a good seal against leakage when closed, plus the pneumatic actuator that moves the disc quickly and accurately. Many models have wafer-style bodies that fit neatly between existing pipe flanges, making them easier to install compared to other valve types. When shopping for these valves, checking ANSI ratings becomes essential because they tell engineers what pressure levels and temperatures the valve can handle safely across different operating environments.

Role in Fluid Control Systems

Pneumatic butterfly valves are critical components in fluid control systems, helping regulate flow rates while keeping system pressure stable. When operators adjust the valve's position, they essentially fine tune both pressure levels and flow volume to match what different processes need across sectors like petrochemical plants or wastewater treatment facilities. These valves have been engineered to reduce turbulence inside pipelines, which cuts down on wasted energy and makes the whole system run smoother. Many pneumatic models now work seamlessly with digital control panels, sending real time data back to central monitoring stations for better process management. Safety remains a big concern too, since these valves stop dangerous backflow situations that could damage equipment or create hazardous conditions. Their compatibility with contemporary automation technologies means pneumatic butterfly valves aren't just functional parts anymore but integral pieces of sophisticated fluid handling systems used throughout modern manufacturing operations.

By comprehending these fundamental aspects, one can effectively utilize pneumatic butterfly valves in various applications, capitalizing on their versatility and reliability.

Working Mechanism of Pneumatic Actuation

Pneumatic Actuator Operations

Pneumatic actuators form a key part of fluid control systems, converting compressed air power into mechanical movement that opens and closes butterfly valves throughout industrial facilities. The conversion happens through either linear or rotary motion patterns, though rotary versions tend to work better for butterfly valves because they just plain get the job done faster. Actuators come in different setups depending on what's needed in the field. Some are double acting while others have spring return mechanisms, each affecting how they actually perform day to day. When talking about fast response times, these actuators really shine in situations where quick adjustments matter most, like during emergency shutdowns or when fine tuning process parameters on the fly. But keep in mind that things like inconsistent air pressure levels or extreme temperatures can throw a wrench in performance, so plant engineers need to check them regularly to keep everything running smoothly and avoid unexpected downtime.

Integration with Butterfly Valve Systems

When pneumatic actuators get paired with butterfly valve systems, it really makes automating flow control much smoother and more accurate than traditional methods. These setups work especially well when connected to things like PLCs or programmable logic controllers, which basically tell the actuators exactly what to do with pinpoint accuracy. This cuts down on mistakes that happen when people have to manually adjust valves all the time. Across manufacturing plants and processing facilities, how well actuators fit with butterfly valves determines if a system will handle different tasks or just stick to one job. Getting everything aligned properly during installation matters a lot too because even small errors here can cause big problems later on. Most engineers run computer models first before installing anything in the field. These simulations help spot potential issues early so when the real equipment goes in place, it works reliably without wasting time or resources fixing things after deployment.

Fail-Safe Features and Emergency Shutoff

Pneumatic butterfly valves come with built-in fail safe mechanisms that will shut the valve automatically when there's a power outage, which helps keep systems intact even in tough situations. The emergency shut off feature really matters for stopping major accidents, particularly in dangerous areas where following safety rules isn't optional but mandatory. Testing these fail safe functions regularly makes all the difference for being ready when something goes wrong, and this practice aligns well with what most industries require for safety. Many valve designs actually include backup systems as standard, creating extra protection against malfunctions. This kind of redundancy not only keeps operations running smoothly but also guards against expensive equipment damage and protects workers who might otherwise face serious risks if valves were to fail unexpectedly during normal operation.

Advantages in Industrial Applications

Energy Efficiency and Cost Savings

Pneumatic butterfly valves stand out because they save energy, mainly since they create less pressure loss across the system. This means companies spend less on pumping fluids through pipelines. The ability to finely tune flow rates makes a big difference too, cutting down on operational expenses while supporting greener production methods. Manufacturing plants that switch to better valve technology often see around 30% reduction in energy bills according to industry reports. Maintenance matters a lot for keeping these valves working right over time. A simple check every few months prevents breakdowns and extends service life by years, which saves money compared to replacing old valves. Working closely with equipment suppliers during initial setup helps find the most efficient models available. Many businesses report significant cost savings within just a couple of years after making this kind of investment.

Reliability in High-Pressure Environments

Pneumatic butterfly valves work great in high pressure situations, which makes them a popular choice across oil and gas operations plus chemical processing plants. Most manufacturers build these valves using strong metal alloys that can take whatever punishment comes their way during regular operation. Before installation, companies run extensive tests to make sure they hold up when things get really intense down there at the worksite. Field engineers consistently report back that having valves that won't crack under varying pressure levels saves time and money in maintenance costs. Getting proper certification from bodies like ISO isn't just paperwork either it actually proves these valves can handle the tough requirements set by safety regulations and performance expectations in industrial settings.

Compatibility with Automated Control Systems

Pneumatic butterfly valves work really well with automated systems such as SCADA and DCS, making it easier to monitor and control processes across different facilities. When factories automate their operations, they save time on manual tasks and get things done faster overall. The way these systems communicate with each other is pretty flexible too, so they can respond quickly when something changes in the fluid control setup. For instance, plants that switch to automated valves often see better production rates because there are fewer mistakes and less equipment sitting idle. Companies that spend money on good automation tech also gain valuable insights from collected data, helping managers make smarter choices about maintenance schedules and operational adjustments.

Common Applications Across Industries

Oil and Gas Pipeline Management

Pneumatic butterfly valves play a key role in oil and gas pipeline management where they control flow rates and manage pressure effectively. These valves respond fast when there's sudden changes in demand, something that keeps operations safe while also boosting overall efficiency across the pipeline network. Most manufacturers stick to API standards because these benchmarks ensure their equipment works reliably even under tough conditions like extreme temperatures or corrosive environments. Maintenance crews typically inspect these valves every few months to catch any signs of wear before they become serious problems. A small leak today could turn into a major disaster down the road if left unchecked. Beyond just safety concerns, proper valve operation actually saves money too. When everything works right, pumping stations consume less energy throughout the system, making resource management much more cost effective for operators in the long run.

Chemical Processing Systems

Pneumatic butterfly valves play a critical role in the chemical industry where precise control matters most, particularly when handling dangerous substances. Most manufacturers build these valves from materials that resist corrosion since they need to survive in harsh chemical processing conditions. Regular maintenance isn't just recommended it's absolutely necessary according to safety standards so these vital parts keep working properly without fail. Switching to automated versions of these pneumatic valves gives better control over processes which means higher quality end products. And let's face it, nobody wants accidents. That's why ongoing monitoring remains essential not only for meeting regulatory requirements but also for keeping workers safe day after day.

Water Treatment Facilities

Pneumatic butterfly valves are pretty much workhorses in water treatment plants, controlling flow rates during filtration processes and when adding chemicals to the water. Keeping these flows consistent is actually what keeps tap water safe enough to meet all those government regulations we have in place. What makes these valves so valuable is their ability to adapt quickly when conditions change throughout the day. Operators can tweak settings on the fly if there's sudden demand spikes or unexpected changes in raw water quality. Regular maintenance checks are absolutely critical too. A simple overlooked seal replacement or worn component can lead to major disruptions downstream. The good news? Recent innovations in valve design are helping treatment facilities reduce waste and energy consumption while still maintaining strict quality controls. These improvements aren't just about saving money either they directly support wider sustainability initiatives across the entire water sector.

HVAC Air Flow Regulation

Pneumatic butterfly valves show up all over HVAC systems these days because they do such a good job controlling airflow and keeping buildings at comfortable temperatures without wasting power. What makes them special is how accurately they can adjust airflow depending on who's actually in the space. For instance, when offices empty out after hours, these valves automatically dial back the flow, saving money on electricity bills without making anyone uncomfortable during regular operations. Keeping these valves properly maintained matters a lot too since even small air leaks can seriously cut down on system efficiency and jack up maintenance costs over time. When connected to modern smart building platforms, they become even more valuable tools for monitoring indoor air quality and watching exactly how much energy different areas consume throughout the day. As building codes get stricter about energy usage and property owners look for ways to cut operating expenses, manufacturers keep coming up with better valve designs that meet these demands while helping buildings run greener.

Maintenance Best Practices

Routine Inspection Protocols

Regular checkups for pneumatic butterfly valves really matter if we want them to last longer and work properly over time. The actual inspection process includes looking for leaks around the seals, checking how much wear has built up on different parts, and making sure the valve opens and closes correctly when it should. Most industries suggest doing these inspections based on how hard the valves are working each day. Keeping records of what gets found during inspections helps track how well the valves are holding up and catches small problems before they turn into big headaches down the road. Getting staff trained in good inspection methods makes a huge difference too. When people know exactly what to look for and how to test things properly, the whole maintenance system becomes more reliable and actually works as intended instead of just going through the motions.

Lubrication and Seal Replacement

Getting the right amount of lubricant on those moving parts inside pneumatic butterfly valves makes all the difference for smooth operation and cutting down wear over time. Stick to the lubrication schedule recommended by the manufacturer and watch how much longer these valves actually last in real world conditions. Don't forget about those seals either they need replacing regularly, either following what the factory says or when they start showing signs of wear. This helps keep everything sealed properly and stops those annoying leaks from happening. The type of lubricant matters too different materials react differently so always check what works best for each application. Good maintenance records should track when lubrication happened and how the seals look during inspections. Investing in quality seals and decent lubricants pays off big time fewer breakdowns mean less downtime and money spent fixing problems that could have been avoided.

Troubleshooting Solenoid Valve Issues

When dealing with problems in solenoid valves, it helps to start by looking at what might be wrong with either the electricity or air supply first. A lot of times, these valves just won't open all the way or shut properly, something that usually fixes itself after making small tweaks or giving them a good clean out. Checking those electrical parts regularly makes sense too since this keeps things running better and cuts down on surprises when they stop working. For replacing old valves, look at how long they've been used and their past performance records instead of guessing randomly. People who handle maintenance need proper training on fixing these kinds of issues so there's less time wasted getting everything back online. Getting staff comfortable with basic diagnostics really matters for keeping operations moving without constant interruptions.