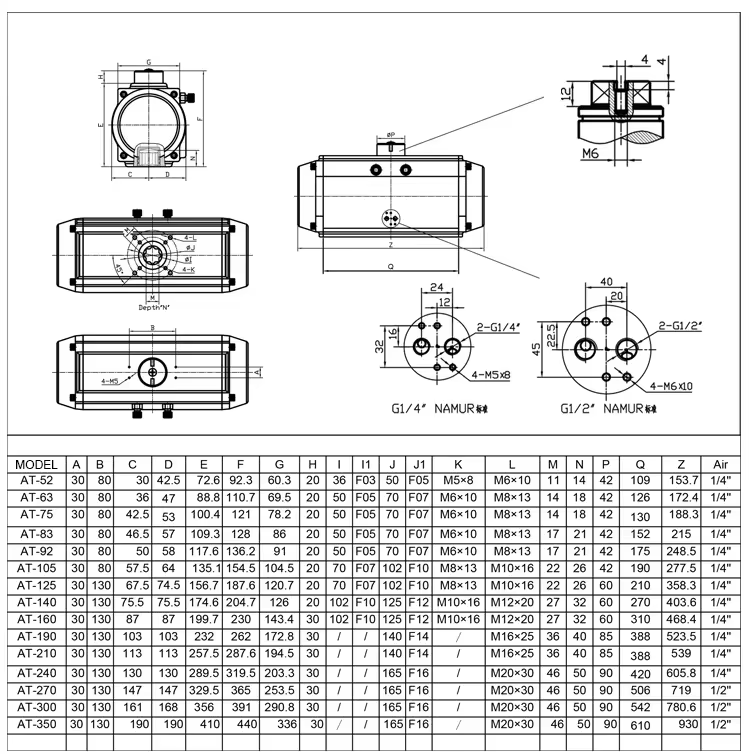

FOLS Single Acting Spring Return Pneumatic Actuator

Spring Return Pneumatic Actuator with rack and pinion system. Opens with pneumatic pressure and interrupts with closure.

|

Actuator Type |

Pneumatic spring return |

|

Air Supply Pressure |

2.5 to 8 bar |

|

Construction |

Aluminum alloy |

|

Rotary movement |

0° to 90° |

|

Surrounding Temperature |

-40 to 160° |

|

Protection Class |

IP65 |

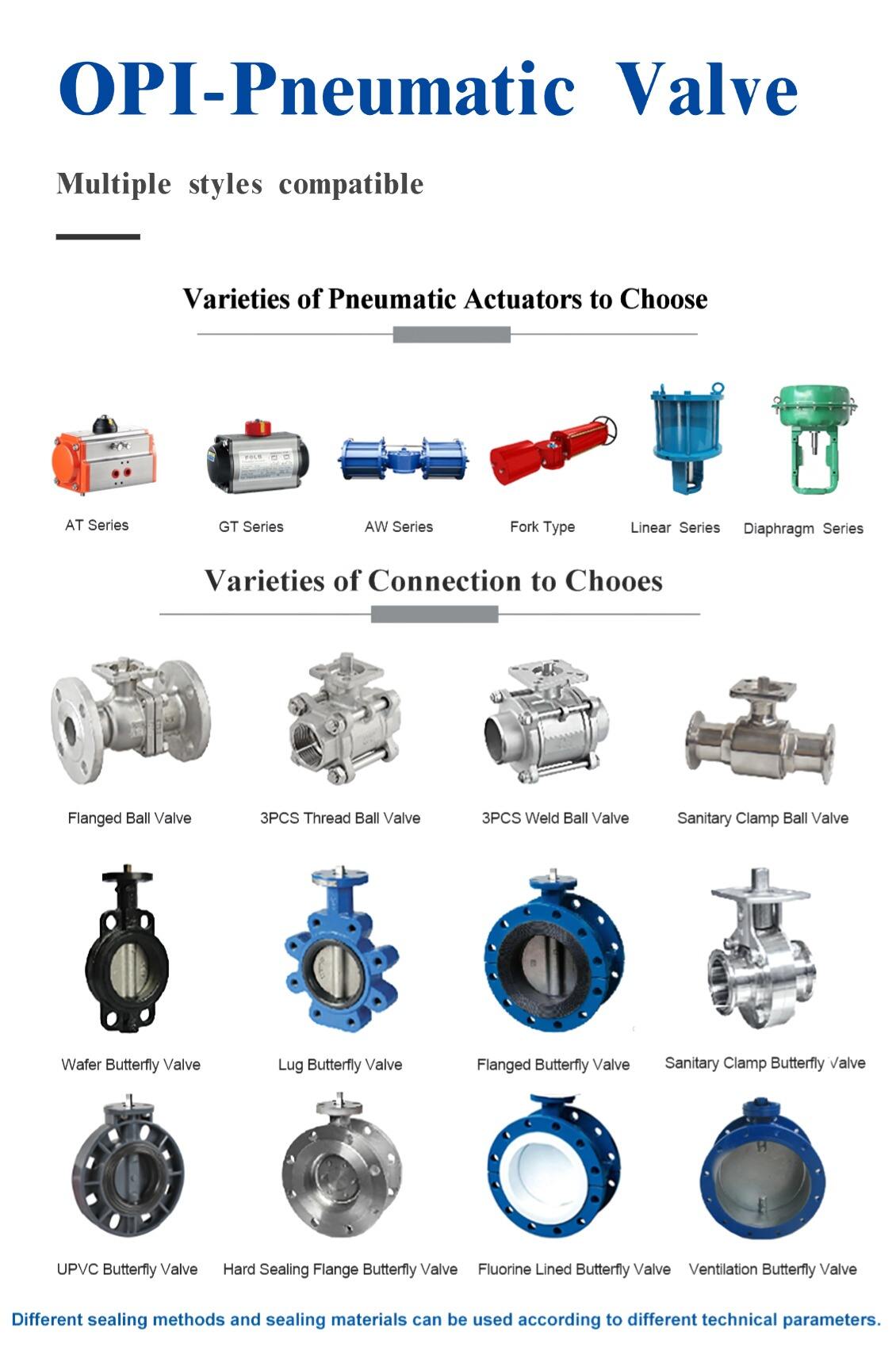

- Overview

- Recommended Products

Spring Return Pneumatic Actuator

Short Description:

FOLS offers double-acting and single-acting rack and pinion pneumatic actuators for your specific needs.

Spring Return Pneumatic Actuator with rack and pinion system. Opens with pneumatic pressure and interrupts with closure. Air supply power between 2 bar and 8 bar. Torque output between 5.7Nm and 2792Nm.

FOLS is a manufacturer of spring return pneumatic actuators and double acting pneumatic actuators for an array of uses.

Select the suitable actuator with our assistance!

Air supply pressure the minimum supply pressure is 2.5 Bar,the maximum supply pressure is 8 Bar.

Single acting pneumatic actuator parameters:

· Operating Media: Dry or lubricated air, or the non-corrosive gases the maximum particle diameter must less than 30 μ m.

· Operating temperature: Standard:-20℃~+80℃;

· Low temperature:-35℃~+80℃;

· High temperature:-15℃~+150℃

· Travel adjustment: Have adjustment range of + 5° for the rotation at 0° and 90°.

· Application: Either indoor or outdoor.

Features Of Single Acting Spring Return Pneumatic

Actuator: Spring return pneumatic actuator with feature of safe Rack and pinion pneumatic actuator with high output torque Easy to install and change the number of spring Weather-proof.

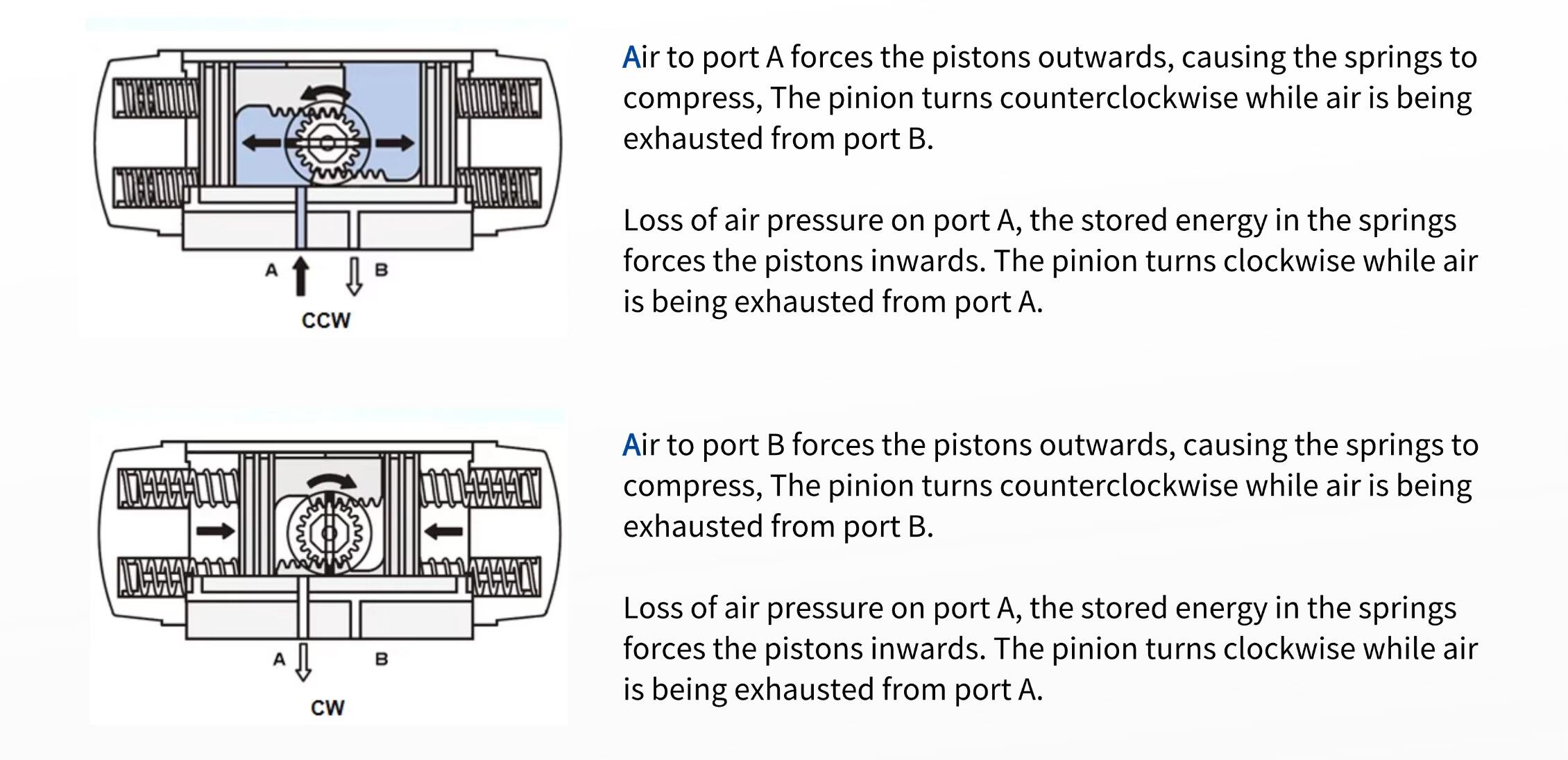

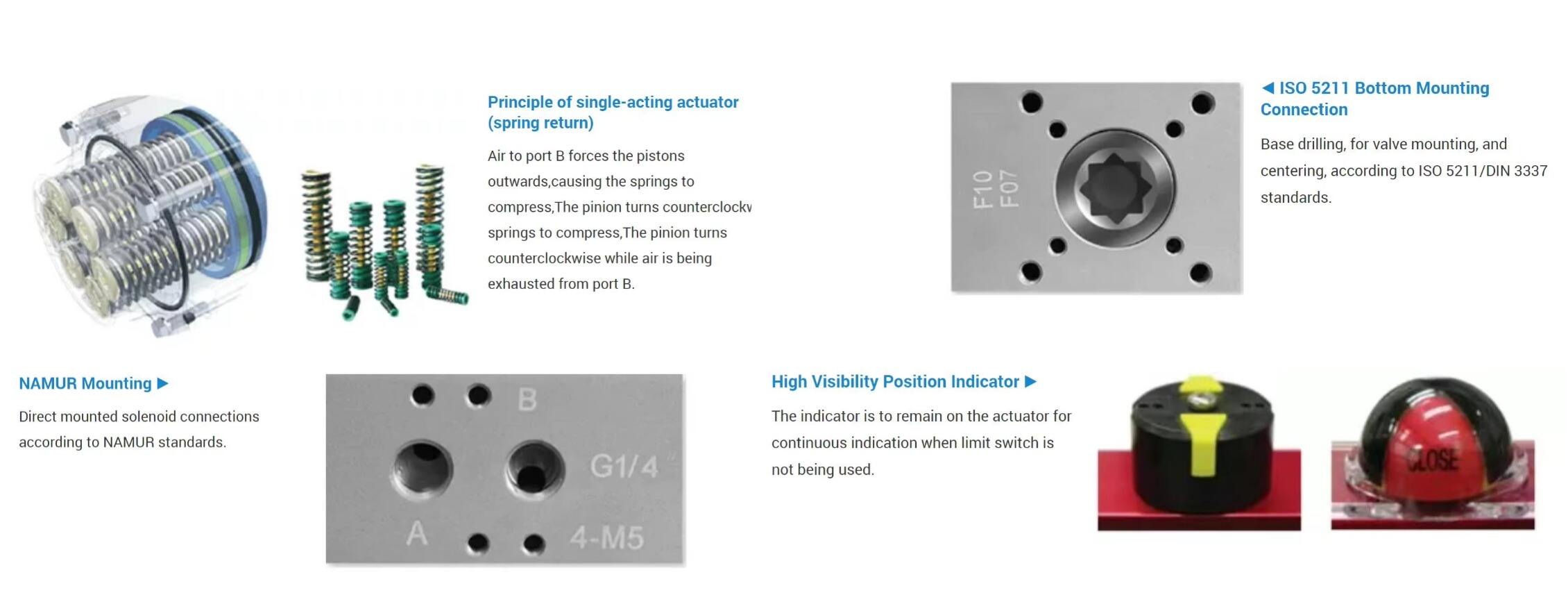

Operating principle of single acting pneumatic actuator:

Features Of FOLS Double Acting Pneumatic Actuator:

Responsive and fast open and close.

Rack and pinion pneumatic actuator with features of high output torque ISO5211 mounting for ball valve and butterfly valve.

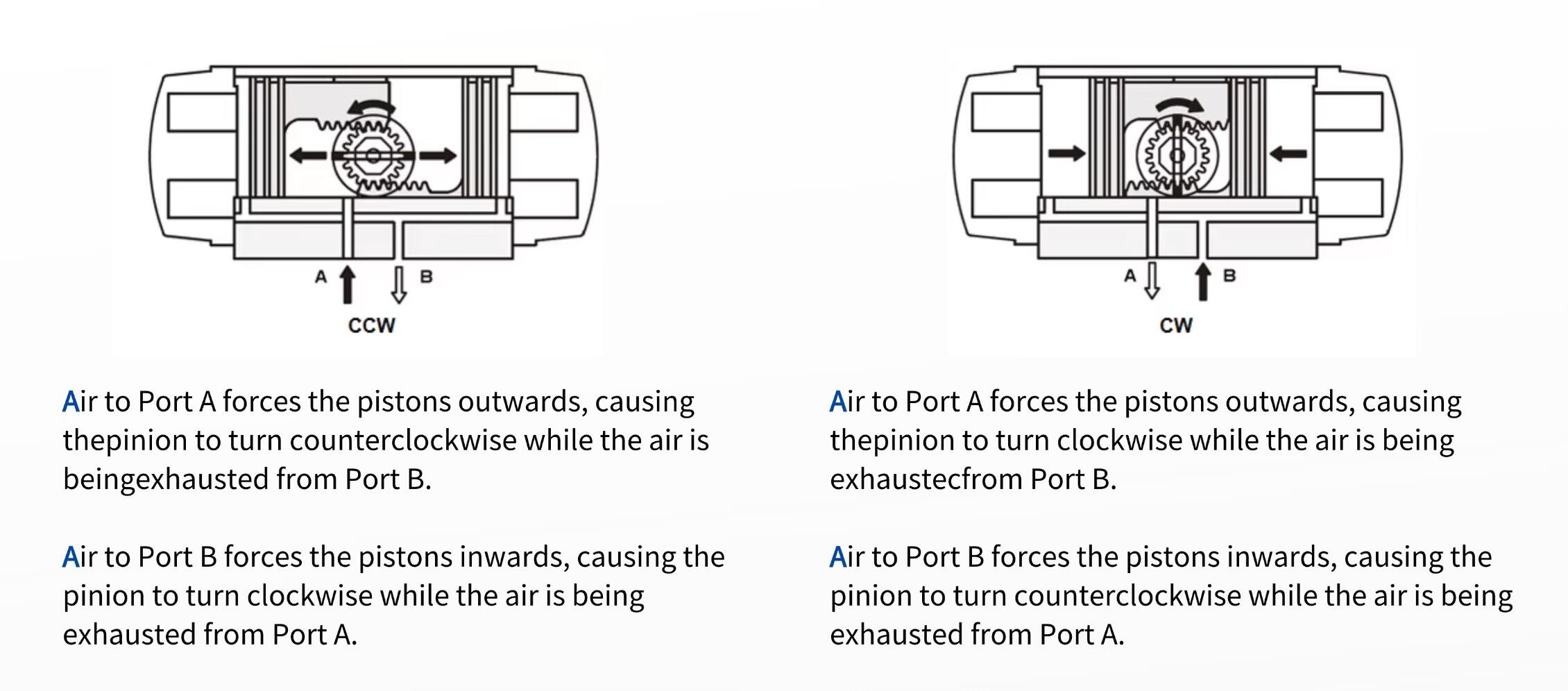

Operating principle of double acting pneumatic actuator:

· Preloaded coating springs are made from the high-quality material for resistance to corrosion and longer service life, which can be demounted safely and conveniently to satisfy different requirements of torque by changing the number of springs.

· ISO5211 standard for ball valves or butterfly valves.

· DIN3337 and NAMUR Standard for pneumatic accessories.

· Twin rack pistons are made from die-casting aluminum treated with hard anodized or made from cast steel with galvanization, symmetric mounting position, long cycle life and fast operation, reversing rotation by simply inverting the pistons.

· It has a number of springs inside and will auto return once air is interrupted and it could keep the valve and project safe.

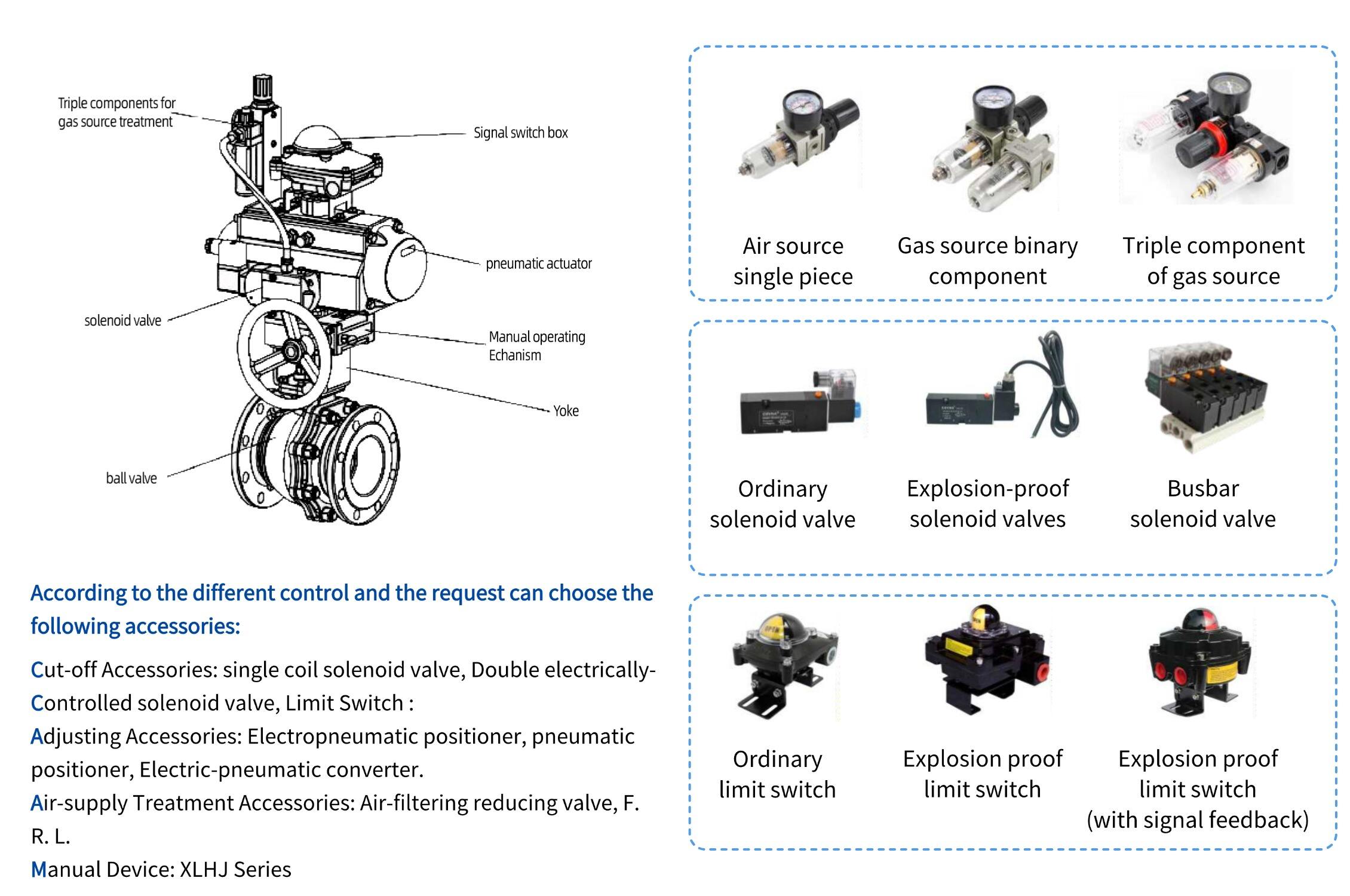

According to the different control and the request can choose the following accessories:

· cut-off Accessories: single coil solenoid valve, Double electrically-controlled solenoid valve, Limit switch

· Adjusting Accessories: Electropneumatic positioner, pneumatic positioner, Electric-pneumatic converter.

· Air-supply Treatment Accessories: Air-filtering reducing valve, F. R. L.

· Manual Device: XLHJ Series

Item |

Single Acting、Double Acting Pneumatic Actuator |

Acting Mode |

Double Acting、Spring Return (Single Acting) are Available |

Output Torque |

14 to 1170 Nm |

Air Supply Pressure |

2.5 to 8bar |

Lifespan |

1,000,000 (1 Million) Times |

Angle of Rotation |

90° ±4° |

Shell Material |

Aluminum Alloy Extruded |

Applicable Media |

Filtered, Dry Compressed Air, Non-Corrosive Medium |

Ambient Temp. |

Standard Type: -20 to +80°C (-4 to 176°F) |

Optional Accessories |

Namur Solenoid Valve, Limit Switch, F.R.L, Position Indicator, Manual Device |

Application |

Food & Beverage, Refining, Desalination, Petrochemical, Chemical, Pharmaceutical, Textile, Pulp & Paper, Mining, Marine and Power Industries |

Lubrication |

There is no need for lubrication for standard type under normal operating conditions. Special lubricants should be used under low or high temperature operating conditions. |

FOLS Pneumatic Sanitary Ball Valves provide you with a safe and reliable fluid control solution. Sanitary ball valves are made of safe materials. Both the inside and outside of the valve are polished and sterilized. What's more, the ball valve incorporates food-grade seals to avoid food contamination.

Use with pneumatic actuators for easy remote control. Provide you with cost-effective and intelligent fluid control solutions.

If you have any demand for actuator or wanna get a free actuator solution, please contact us [email protected]

For more product inquiries, please contact us www.folsv.com/contact

· Confirm the valve size you need. We offer this Pneumatic valve in 2in to 20in.

· Confirm the valve body material you need. We offer this pneumatic valve in WB, Cast steel, Stainless steel 304, Stainless steel 316 material.

· Confirm the connection standard. We offer this motorized ball valve in ANSI, JIS, DIN, and UK standard.

· Confirm the pressure and working temperature. Pressure and temperature are the important points and those may affect the cost.

· Confirm the voltage you need. The right voltage could help your valve operate better.

· Tell us your medium. Different medium has different features and we will help you to select the valve basic on the medium requirements

· Confirm the actuator type you need. We have Double acting or Single Acting Spring Return Pneumatic Actuator for your project.

· Any requirements please tell us like core material, sealing material, or connection standard. We could help you to custom the valve you need.

· More information, please send message to us. Quote will be provided within 2 hours!

Installation Instruction

· Tightening the seal between the valve and the actuator: Remove the four bolts underneath the actuator. Separate the actuator from the valve

· Tighten the nut on the top of the valve body.

· Place the actuator back on the valve and screw everything back into place

· Tightening the seals between the valve and the inlet/outlet ports:Remove the torgue bolts and check for any debris or damage to the gaskets.

· Use a torque wrench or other consistent method of tightening the torque bolts to reconnect the inlet and outlet ports.

Packaging and transportation:

As a professional manufacturer of pneumatic valves, FOLS aims to provide customers with the highest quality products, the most competitive prices, punctual delivery and comprehensive warranty services. We offer a full range of services from start to finish, including consultation and after-sales service, providing comprehensive support to ensure that you are by your side at every stage of the project.

Company:

FOLS is committed to providing customers with the highest quality products at the most competitive prices, on time delivery, and comprehensive warranty services. From beginning to end, we offer comprehensive services, including consultation to after-sales service, providing all-round support, to ensure that you have our company's company throughout each stage of the project. 45-year valve drive device manufacturer Accepts large-scale customization. 2 production bases, sufficient inventory,

Short delivery period, same-day shipment.

Using imported manufacturing equipment from Germany, 100% quality inspection before shipment, quality guaranteed. Provide industrial standard 1-year (12 months) warranty. Certified by ISO 9001, additional certifications include CE, TUV, RoHS, SGS, BV, explosion-proof and fire safety. Provide OEM/ODM services. Can produce JIS 5K/10K, ANSI 150lb/300lb/600lb/900lb standard products. K, ANSI 150lb / 300lb / 600lb / 900lb standard.